London-based Silo Studio was born out of the partnership of Attua Aparicio and Oscar Wanless whilst studying for their Design Products MA at the Royal College of Art (2009-2011). Their strong collaborative work is based on their backgrounds of engineering and design with the focus of their practice aimed at making and developing materials that expose the expressive potential of industrial material; bringing craft and technology together to challenge what ‘materiality’ really is.

Their first artistic endeavour has included the innovation of Not So Expanded Polystyrene (NSEP) which, unlike traditional polystyrene, is expanded after it goes into the mould, therefore producing a denser, stronger and more durable material. The pair have taken the idea further and instead of using industrial metal moulds, have created high tensile textile ones that allow unique and textured forms, only made possible by this method. Using this method to produce a range of furniture including tables, chairs and shelving, the duo were brought to the attention of the Design Museum who nominated them for ‘Designs of the Year’ in 2012.

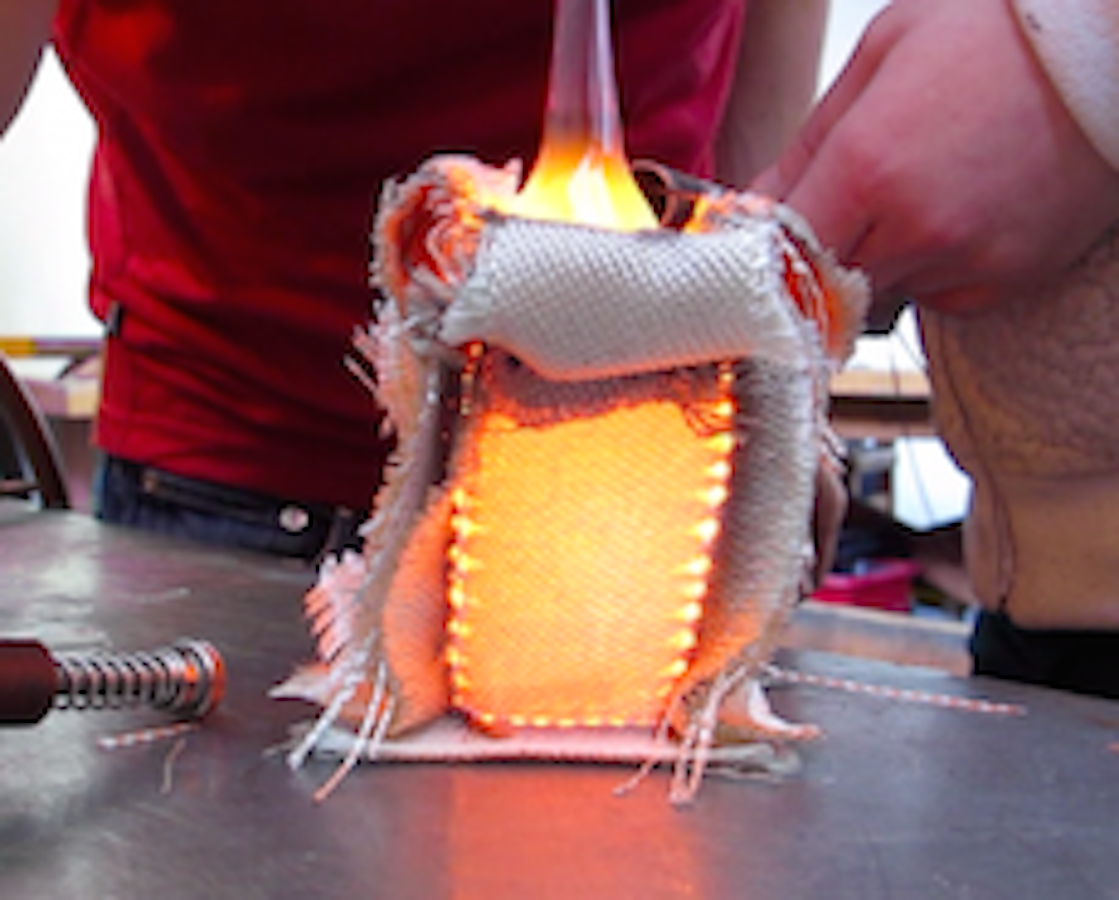

Inspired by the potential of textile moulds, Attua and Oscar have developed ‘textile moulded glass’. Using a high temperature silica textile that remains stable, tensile and flexible at the very high temperatures required to melt glass. The process then involves making hand stitched moulds into which the borosilicate glass is blown to make functional drinking ware and vases. This work has led to a commission for the Danish brand Hay/Wrong for Hay.

A common thread through Silo’s studio practice is to explore variety and uniqueness whilst using moulds, which would normally standardise results. Often Silo use flexible moulds to achieve this, but also looking at other physical principles and using colour to get uniqueness in moulding, such as their most recent project Newton’s Bucket that uses spin casting of multi coloured acrylic reinforced gypsum to freeze liquid flow through inertia and centrifuge to make bowls, creating tools to disrupt and describe the motion, carefully controlling the direction and speed of the rotation before the fluid sets into a permanent concave form.